BARUCH LEL Fixed Gas Detector, For Industrial Use, Sense point XCD

Fixed combustible gas detector is 24-hour online to monitor the leakage of combustible gas 0 to 100% LEL, widely applied in the confined space, gas pipeline area, gas station, material spraying workshop, chemical industry, and other flammable and explosive gas storage area.

Features

- Adopting high precision sensor for accurate gas leak detection.

- Equipped with 3-wire system 4-20mA analog output, relay output, RS485 output (optional).

- Compatible with various controlled alarms, PLC, DCS and other control system, and can be remote monitored.

- Explosion-proof design, fast, reliable and stable.

- Infrared ray controller can remote control the alarm point settings, zero calibration, and address modification.

- Two-stage alarm with sound and light, and the alarm point is settable.

- With self-calibration function, and three standard keys will be used to realize on-site maintenance.

- Can output one or two on-off signals, can drive ventilator, solenoid valve or other external devices.

Specifications

| Model | ATO-YT95H-EX-A |

| Detection Principle | Catalytic Combustion |

| Gas | Combustible Gas (EX) |

| Range (Optional) | 0 to 100% LEL |

| Resolution | 1% LEL |

| Accuracy | ≤±3% F.S. |

| Responce Time | ≤10s |

| Repeatability | ≤±1% |

| Recovery Time | ≤10s |

| Linearity Error | ≤±1% |

| Zero Shift | ≤±1% (F.S./year) |

| Signal Output (Optional) Note | 4-20mA, or RS485 (transfer card included); Relay output: one group of relay output (1NO+1NC, 24V 100mA) for one alarm (default), or two groups of relay output (2NO+2NC, 24V 100mA) for high/low alarm (optional). |

| Alarms | Sound, light |

| Display | High light nixie tube display |

| Installation | Wall-mounted, piping type, flow-type (according to the detected environment) |

| Connection | G1/2 male thread explosion-proof flexible pipe |

| Operating Time | 24h |

| Explosion-proof Grade | Ex d llC T6 |

| Protection Grade | IP65 |

| Certification | CE, ATEX |

| Working Voltage | 12~36V DC |

| Case Material | Die-casting aluminum housing |

| Operating Temperature | -20℃~50℃ |

| Operating Humidity | 0~95%RH (non-condensing) |

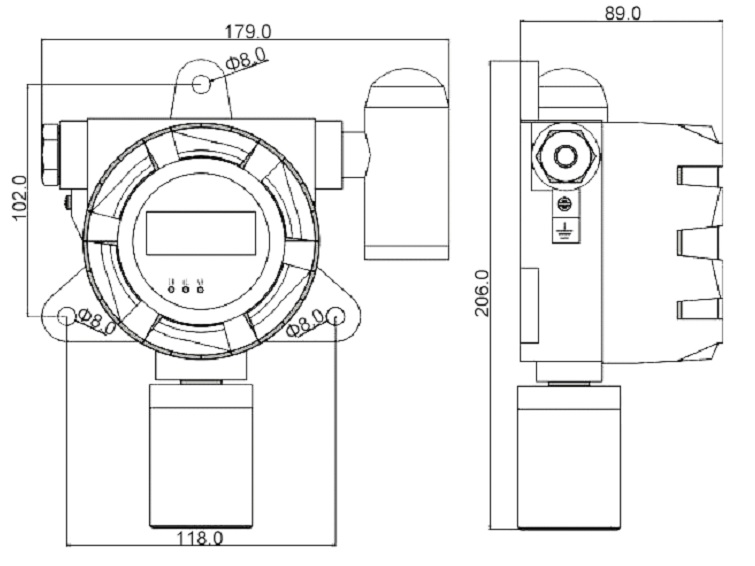

| Dimension | 206*179*90mm |

| Weight | ≤1.6kg |

| Accessories | Power adapter: Input 100-240VAC 50/60Hz, Output 24VDC 2A (Optional USA plug & Europe plug) |

Product diagaram details

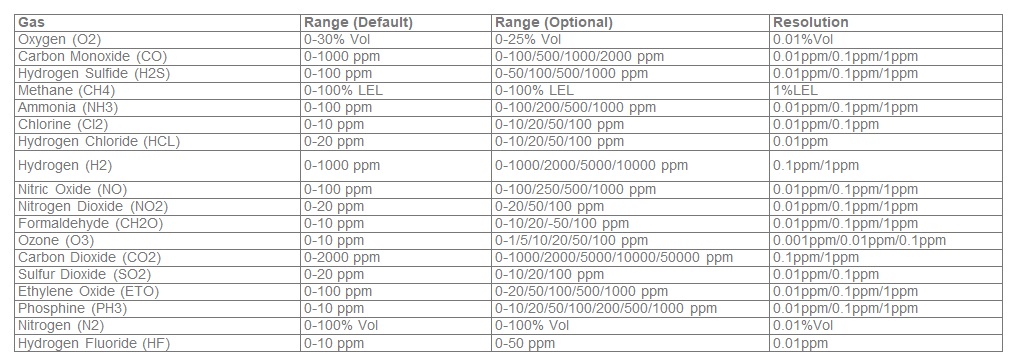

Other Common Gases and Ranges Available for Fixed Gas Detectors

* Some common gases and the measuring ranges are listed in the above table. For more information, please feel free to contact us.

Tips: Installation of Fixed Combustible Gas Detector

The combustible gas detector is used for flammable gas leak detection and alarming. When the combustible gas leaks and the detector monitors that the gas concentration reaches the set critical point, the flammable gas detector will sound an alarm to remind the staff of taking measures, to prevent explosions, fires, and poisoning accidents, thus ensuring safe production. Once fixed combustible gas detector is installed in place, its position is not easy to change. Therefore, something should be noted before installing the detector.

- First of all, it is necessary to find out the place to be monitored where may be leaking points or prone to gas leakage, such as the interface of the pipeline, etc., and analyze the leakage pressure, direction and other factors.

- It also needs to judge the direction of leakage of combustible gas when a large number of leakage occurs according to the air flow direction, wind direction and other specific factors on site.

- According to the density of the leaked gas (greater or less than air) and the trend of air flow, the downstream position of the gas flow can be considered as the initial installation point.

- Figure out the leakage state of the leak point, micro leak or spray-like leak. If it is micro leakage, the combustible gas detector should be installed closer to the leakage point. If the leakage is spray-like, it should be installed slightly away from the leak point.

- The installation height of the outdoor gas detector can be selected according to the density of the measured gas. A very important thing to understand is that the detector should be installed on the downwind side.